SP-RAMP Logic Block Documentation

Overview

The SP_RAMP function block is designed to smoothly increase or decrease a set point (SP) from its current value to a target value over a predefined duration.

This block allows for bidirectional ramping — meaning it can both ramp up and ramp down.

By employing the SP_RAMP block, transitions are controlled, systematic, and safe, helping to avoid sudden fluctuations that could destabilize the process or stress equipment.

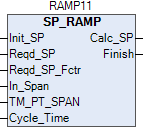

In the above picture we are showing the SP_RAMP block.

Functional Description

- This block gradually adjusts the set point from

Init_SPto the scaledReqd_SPover the time defined byTM_PT_Span. - It ensures a linear transition (either increment or decrement) within the defined cycle time.

- The output

Finishis set toTRUEwhen the transition is complete.

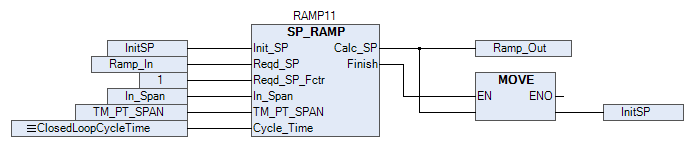

In the above picture we are showing the example of connecting the pins.

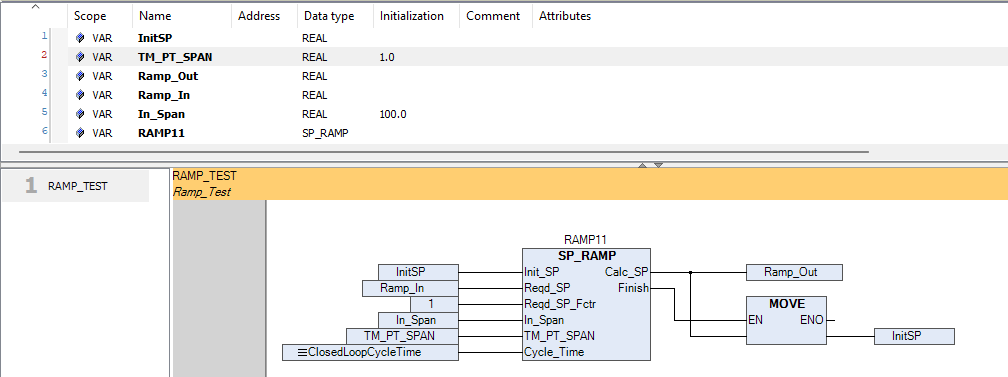

In the above picture we are showing the example of using this block.

Pins Information

| Signal Name | Type | Description |

|---|---|---|

Init_SP |

REAL |

Initial set point value from which the ramp will begin |

Reqd_SP |

REAL |

Target set point value |

Reqd_SP_Fctr |

REAL |

Factor applied to scale the required set point (e.g., for percentage adjustment) |

In_Span |

REAL |

Input span limit (used to define allowable operating range) |

TM_PT_Span |

REAL |

Base time span required for the set point to move from minimum to maximum |

Cycle_Time |

REAL |

Execution cycle period of the block (time step for calculations) |

Calc_SP |

REAL |

Intermediate calculated set point during ramping |

Finish |

BOOL |

Status output: TRUE when ramping is complete, otherwise FALSE |

Operational Behavior

-

Initialization:

The block readsInit_SPas the starting point and computes the target usingReqd_SP × Reqd_SP_Fctr. -

Ramping:

- The block gradually increases or decreases the set point.

- The speed of ramping depends on the ratio of

TM_PT_SpanandCycle_Time. - The

Calc_SPoutput updates each cycle to reflect the current ramp position.

-

Completion:

Once the calculated set point reaches the scaled target value, the block setsFinish = TRUE.

Example Use Case

For example, in a flow control application, the operator might need to increase flow from 20% to 80% over 10 minutes.

Instead of jumping directly, the SP_RAMP block will gradually adjust the set point within the defined TM_PT_Span, ensuring smooth and stable process changes.

Similarly, in a shutdown sequence, the same block can gradually decrease the set point to zero, avoiding abrupt changes.

Best Practices

- Set

TM_PT_Spanaccording to system dynamics — too short may cause oscillations, too long may delay response. - Use

Reqd_SP_Fctr = 1.0if scaling is not required. - Ensure

Cycle_Timeis correctly configured to match task execution cycles. - Always check

Finishbefore initiating dependent process steps. - Suitable for PID transitions, gradual valve openings, pump startups/shutdowns, and flow/temperature adjustments.

The

SP_RAMPblock provides a flexible, safe, and structured method for implementing both set point ramp-ups and ramp-downs, ensuring stability and reliability in automated processes.