LIN10P (10-Point Linearization Block Documentation)

Overview

The LIN10P block is a functional component used in industrial automation systems to convert non-linear analog inputs into linearized outputs using a predefined set of reference (X, Y) points. It enables improved accuracy for devices such as pressure, level, or flow transmitters that exhibit non-linear characteristics.

- The logic performs piecewise linear interpolation using up to 10 configurable (X, Y) pairs.

- It significantly improves measurement accuracy, simplifies control logic, and enhances system stability and reliability.

- LIN10P is especially useful where high-precision scaling of sensor data is needed prior to display or control action.

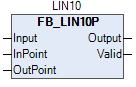

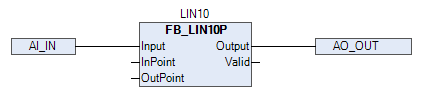

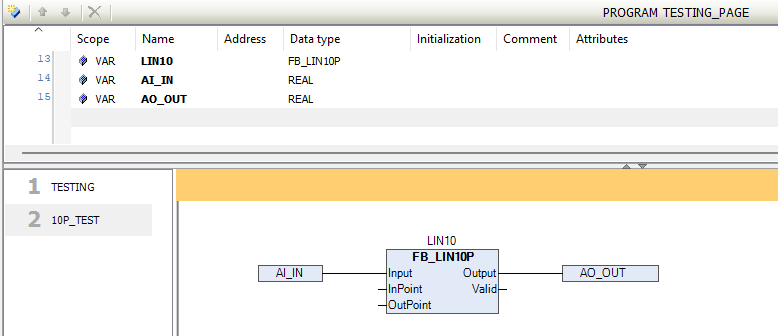

Logic Block Illustration

The FB_LIN10P block provides a clear method to linearize raw analog input from field instruments.

A visual representation of the LIN10P logic block in the programming environment.

The above image illustrates how to connect the LIN10P block within logic for input signal scaling.

Pins Information

| Signal | Type | Description |

|---|---|---|

Input |

REAL | The raw process value to be linearized. |

InPoint |

ARRAY[1..10] OF REAL | X-axis reference points (raw sensor values). Must be in ascending order. |

OutPoint |

ARRAY[1..10] OF REAL | Y-axis scaled output values corresponding to each InPoint. |

Output |

REAL | Interpolated and scaled output value. |

Valid |

BOOL | TRUE if valid interpolation is performed (i.e., at least 2 valid points). |

Operational Summary

- The block checks where the

Inputvalue lies between any two adjacentInPointvalues. - It then performs linear interpolation using the corresponding

OutPointvalues. - If input falls outside the configured range or fewer than two points are valid, the output is marked invalid via the

Validbit. - This block has no faceplate. It is typically used internally with other logic and analog scaling blocks.

Example Use Cases

- Converting a non-linear tank level (mm) to actual volume (liters).

- Compensating for non-linearity in differential pressure-based flow measurement.

- Custom calibration curves for unusual sensors.

Training Demo Video

Demonstration video is available , How to use the Daca Logic Block through Library:

LIN10P Block Demo - TPW Logic Setup

Best Practices

- Ensure InPoint values are strictly increasing (ascending) to prevent logic errors.

- Do not use duplicate X-values in

InPointarray. - Always check

Validoutput before usingOutputin downstream logic.

Tip:

This block is ideal for compensating non-linear device behavior in critical process loops where precision and repeatability are essential.