PID-MR Controller Logic Documentation

Overview

The Manual Reset feature in the PID-MR block allows operators to intervene and override the PID output when necessary. This is particularly useful during startup, maintenance, or abnormal operating conditions.

When Manual Reset is active:

- The External MV (Manipulated Variable) input becomes active.

- The controller bypasses PID computation and directly outputs the value provided by the

EXT_MVinput. - The operator can manually control the process output until automatic control is restored.

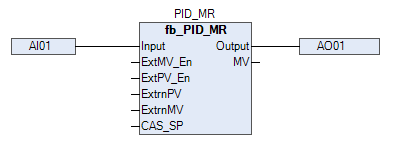

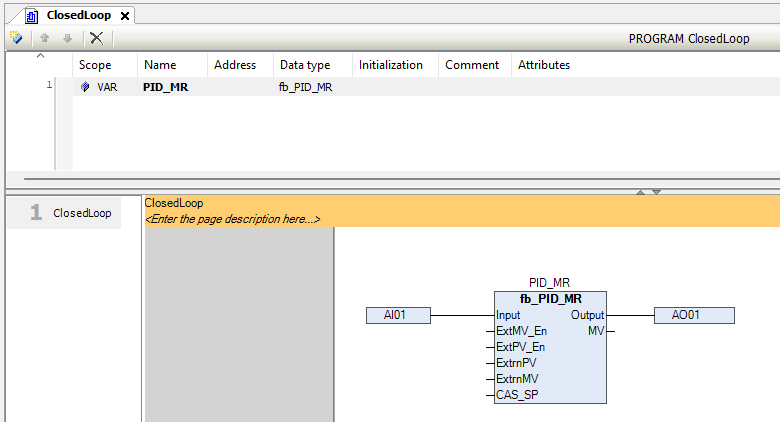

Logic Block Illustration

In above picture, we are showing inputs and output of PID-MRET block.

In the above picture, we are showing that how to use the PID-MR block.

PID_MR Block – Pins Information

| Signal | Type | Description |

|---|---|---|

INPUT |

WORD | Raw input from analog channel |

PV_LO |

REAL | PV low scaling range |

PV_HI |

REAL | PV high scaling range |

RTN_ACK_REQD |

BIT | Return-to-Normal condition requires acknowledgment |

ACK |

BIT | Alarm acknowledgment input |

Acknowledged |

BIT | Alarm acknowledgment status output |

WireBreak |

BIT | Output TRUE when wire break detected |

WireShort |

BIT | Output TRUE when wire short detected |

PV_LL_ALM |

BIT | High when PV falls below very low limit |

PV_LO_ALM |

BIT | High when PV falls below low limit |

PV_HI_ALM |

BIT | High when PV exceeds high limit |

PV_HH_ALM |

BIT | High when PV exceeds very high limit |

PVLL |

REAL | Very low PV alarm limit |

PVLO |

REAL | Low PV alarm limit |

PVHI |

REAL | High PV alarm limit |

PVHH |

REAL | Very high PV alarm limit |

HYST |

REAL | Hysteresis for PV alarm activation/deactivation |

FILTER |

REAL | Filter time constant to reduce PV noise |

TagName |

STRING(10) | PID block tag name (Max. 10 characters) |

Desc |

STRING(12) | Description or label (Max. 12 characters) |

P |

REAL | Proportional gain |

I |

REAL | Integral time constant |

D |

REAL | Derivative time constant |

MVLO |

REAL | Minimum output limit for MV (%) |

MVHI |

REAL | Maximum output limit for MV (%) |

PID_OP |

REAL | Output set manually in manual mode (%) |

MODE |

BYTE | 0: Manual, 1: Auto, 2: Cascade, 3: Remote |

Output |

WORD | Final output mapped to raw analog value |

SP_TRACK |

BIT | TRUE: Setpoint follows PV (useful in switching modes) |

CTRL_ACTN |

BIT | TRUE = Direct acting; FALSE = Reverse |

ExtPV_En |

BIT | Enable external PV signal |

ExtrnPV |

REAL | External PV value (used if ExtPV_En is TRUE) |

PV |

REAL | Process variable (scaled) |

SV |

REAL | Setpoint value (active) |

MV |

REAL | Manipulated variable (controller output) |

LOC_SP |

REAL | Local setpoint |

REM_SP |

REAL | Remote setpoint |

CAS_SP |

REAL | Cascade setpoint |

SP_HI_LM |

REAL | Maximum limit for setpoint |

SP_LO_LM |

REAL | Minimum limit for setpoint |

IN_LO |

REAL | Scaling lower range of analog input |

IN_HI |

REAL | Scaling upper range of analog input |

OP_LO |

WORD | Raw analog output low limit |

OP_HI |

WORD | Raw analog output high limit |

DIR |

BIT | Output direction: FALSE = Direct, TRUE = Reverse |

OP_LL_ALM |

BIT | Output very low alarm |

OP_LO_ALM |

BIT | Output low alarm |

OP_HI_ALM |

BIT | Output high alarm |

OP_HH_ALM |

BIT | Output very high alarm |

OPLL |

REAL | Output very low limit |

OPLO |

REAL | Output low limit |

OPHI |

REAL | Output high limit |

OPHH |

REAL | Output very high limit |

HYST (AO) |

REAL | Hysteresis for output alarm handling |

Alarm Handling

- All alarms (PV_LL, PV_LO, PV_HI, PV_HH) activate blinking until the ACK button is pressed.

- On acknowledgment:

- Blinking stops

AcknowledgedbecomesTRUE- Alarm resets after process variable returns to normal with hysteresis.

Control Modes

| Mode | Code | Description |

|---|---|---|

| Manual | 0 |

MV is manually set using PID_OP |

| Auto | 1 |

PID calculates output using SP and PV |

| Cascade | 2 |

SP comes from another block (CAS_SP) |

| Remote | 3 |

SP is taken from REM_SP |

Recommended Settings

- Set P, I, D carefully through Advanced Faceplate.

- Enable

SP_TRACKwhen switching from Manual to Auto. - Use

FILTERto smooth noisy analog inputs.

Use Case:

Perfect for process loops with critical safety where operator acknowledgment is mandatory before returning to auto operations (e.g., tank level, pressure, flow control with alarms).