Visualization Documentation – PID_MR Block

Usage of PID_MR Block through SCADA Template

The PID-MR (Modular PID with Manual Reset) block is used for closed-loop process control, similar to the standard PID block.

It introduces an enhanced Manual Reset (MR) feature to improve safety and control reliability during critical operations.

This block is ideal for applications where the operator must acknowledge or reset the loop before resuming automatic control.

Integrating the PID_MR Block into Visualization steps are given below:

1: Open the Visualization Page

- Launch your CODESYS project.

- Open the visualization page where PID-MR should be placed (e.g.,

Main_HMI,PIDMR_Control).

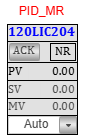

2. Insert the PID_MR Block Icon from Scada_test Visu Page

- Open the Visualization Toolbox Go to Current Project.

- Drag or drop the PID_MR Block icon to your Visualization page.

- Or Just Copy the PID_MR Block Icon from the

Scada_testvisu page and Paste into your Visualization page.

✅ This ensures consistency and ease of reuse.

3: Link to the Logic Block

- Select the PID_MR block icon.

- click on the block icon Properties tab open automatically → Properties.

- Go to the References and Expand the references.

- you will see bl_PID_MR Expand that also.

- set the path in front of the tagPID by Double clicking on empty space and select the required tag.

- Build and run the project.

- During runtime, verify that live values like

PV,SVandMVfunctioning.

PID_MR Block - Visualization Behavior

-

Clicking the Tagname on the icon opens a faceplate popup.

This includes tabs for: -

Basic Tab – Operator view

- Advanced Tab – Engineer view

- Manual Reset Tab (MR) – Reset/Acknowledge functionality

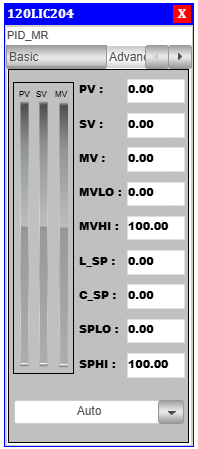

Faceplate - Basic Tab

Shows real-time process control values and limited control buttons.

PID_MR Parameters Details – Basic Tab

| Section | Parameter | Description |

|---|---|---|

| Process Values | PV |

Measured process variable. |

SP |

Setpoint. | |

MV |

Output signal. | |

| Output Limits | MVLO |

Lower output limit. |

MVHI |

Upper output limit. | |

| Setpoint Settings | L_SP |

Lower bound for setpoint. |

C_SP |

Default SP for mode switching. | |

SPLO |

Runtime lower override for SP. | |

SPHI |

Runtime upper override for SP. | |

| PV Bar | PV |

On the left side there is PV bar which show the PV value in visual form. |

| SV Bar | SV |

On the left side there is PV bar which show the SV value in visual form. |

| MV Bar | MV |

On the left side there is PV bar which show the MV value in visual form. |

| Mode Selector | Mode |

Select the mode of the PID By clicking on the dropdown arrow. |

Operator access to SP change may be restricted by access levels.

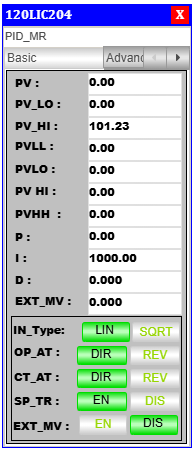

Faceplate - Advanced Tab

Used for controller tuning, input type selection, alarm limits, and behavior configuration.

PID_MR Parameters Details – Advanced Tab

| Section | Parameter | Description |

|---|---|---|

| Process Value | PV |

Real-time process variable input. |

| Process Value Limit | PV_LO |

Low alarm limit for process variable. |

PV_HI |

High alarm limit for process variable. | |

| Alarming Limits | PVLL |

Critical low alarm (very low limit). |

PVLO |

Warning-level low limit. | |

PV HI |

Warning-level high limit. | |

PVHH |

Critical high alarm (very high limit). | |

| Tuning Parameters | P |

Proportional gain. |

I |

Integral time. | |

D |

Derivative time. | |

| External MV | EXT_MV |

External Value |

| Control Type | IN_Type |

Input type for PID: Linear (LIN) or Square Root (SQRT). |

| Control Direction | OP_AT |

Output action: DIR or REV. |

CT_AT |

Controller logic action: DIR or REV. |

|

| SP Tracking | SP_TR |

Enable or disable SP tracking during manual to auto. |

| External MV | EXT_MV |

Enables (EN) or disables (DIS) using value External OR original process value. |

⚠️ Engineer login required to change these values. Misuse can destabilize process control.

Integration Notes

- Ensure

fb_PID_MRinstance is declared in logic before binding. - Use user roles to hide Advanced tabs from basic operators.

Demo / Training Video

🎥 Watch Demo – TPW HMI PID-MR Block Walkthrough

This video shows how to insert, configure, and use the DACA block within a SCADA template project.

Summary

The PID_MR block provides:

- ✅ Manual Reset before auto-mode entry

- ✅ Engineer-level tuning and configuration

- ✅ Process control visibility for operators

Recommended for use in critical loops where safety or operator acknowledgment is essential.