MOV (OPEN/CLOSE) Block Documentation

Overview

The Motorized Operating Valve (MOV) is a vital component in industrial automation and fluid control systems. Designed for ON/OFF control, it facilitates automated flow regulation through electrically driven actuators, governed primarily by a Programmable Logic Controller (PLC).

-

MOVs are extensively used in process industries—such as oil and gas, water treatment, chemical manufacturing, and power generation—where reliable and responsive flow control is essential.

-

It supports both automatic and manual control modes, permission checks, interlock validation, command execution, and signal-based fault detection. The block outputs critical feedbacks to the HMI faceplates for Operator, Basic, Advanced, and Diagnostic levels.

Interaction modes include:

- Block Icon (for real-time feedback and status)

- Faceplates (expandable control panels per user level)

- I/O Pins (to wire control signals and feedbacks in logic)

Block Icon

The MOV block visually represents its status using different color codes and blinking animations:

- MOV in Close Condition

- MOV in Open Condition

- Blinking – MOV in Trip Condition

- Blinking – Open or Close Permission Not Received

- Blinking – MOV Opening

- Blinking – MOV Closing

Note: On Clicking the MOV block icon, the corresponding faceplate below will be displayed.

Faceplate Tabs

In the MOV(Open/Close) faceplate, there are 4 tabs:

-

Operation Tab : For the operation of the motor.

-

Basic Tab : Displays basic feedback and operational summary.

-

Advance Tab : Advanced options for motor configuration and setup.

-

Diagnostics Tab : Shows all feedback and diagnostic parameters.

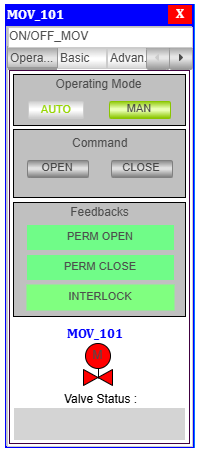

Operator Tab

Operating Mode

- AUTO: For automatic operation

- MAN: For manual operation

After selecting MAN, the operator can control the MOV manually.

Command (Available only in MANUAL mode)

- OPEN: Press to open the valve

- CLOSE: Press to close the valve

Feedbacks

| Feedback Item | Condition | Status Indicator |

|---|---|---|

| PERM OPEN | If open permission is OK | 🟢 = Open Permission OK 🔴 = Open Permission Not OK |

| PERM CLOSE | If close permission is OK | 🟢 = Close Permission OK 🔴 = Close Permission Not OK |

| INTERLOCK | If interlock condition is satisfied | 🟢 = Interlock OK 🔴 = Interlock Active |

| MOV BLOCK ICON | Static display showing MOV block icon with Tag Number | Icon is always visible with corresponding Tag No. |

| Valve Status | Based on combined status of permissions and interlock | Shows Open/Close/Moving based on live MOV condition |

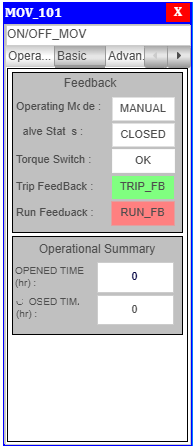

Basic Level Tab

Feedback

| Feedback Item | Condition | Status Indicator |

|---|---|---|

| Operating Mode | Current MOV operating mode | MANUAL / AUTO |

| Valve Status | Valve is currently open or closed | OPENED / CLOSED |

| Torque Status | Torque switch condition | 🟢 = Torque OK 🔴 = Torque Fault |

| Trip Feedback | TRIP_FB signal received |

= TRIP OK = TRIP |

| Run Feedback | RUN_FB signal received |

🟢 = Run Feedback OK 🔴 = Run Feedback Missing |

Operational Summary

- OPENED TIME (hr): Total valve open time

- CLOSED TIME (hr): Total valve close time

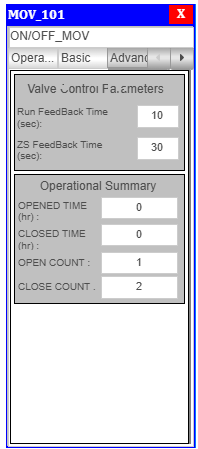

Advanced Level Tab

On clicking the Adva button, the Adva Tab will open.

Only authorized users can access this after logging in.

Valve Control Parameters

- Run Feedback Time (sec): Time to receive RUN_FB

- ZS Feedback Time (sec): Time to receive open/close (ZSO/ZSC) feedback

Operational Summary

- OPENED TIME (hr): Total opened duration

- CLOSED TIME (hr): Total closed duration

- OPEN COUNT: Number of valve openings

- CLOSE COUNT: Number of valve closings

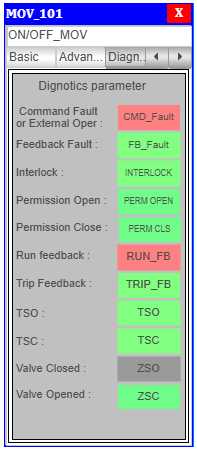

Diagnostic Level Tab

Diagnostic Parameters

| Feedback Item | Condition | Status Indicator |

|---|---|---|

| CMD_Fault | Any fault signal is available | 🔴 = CMD_Fault (Fault Active)🟢 = CMD_Fault (No Fault) |

| FB_Fault | Any fault signal available | 🔴 = FB_Fault (Fault Active)🟢 = FB_Fault (No Fault) |

| Interlock | Interlock status | 🟢 = Interlock (No Interlock)🔴 = Interlock (Active) |

| PERM OPEN | Open permission status | 🟢 = PERM OPEN (Satisfied)🟡 = PERM OPEN (Not Satisfied) |

| PERM CLOSE | Close permission status | 🟢 = PERM CLOSE (Satisfied)🟡 = PERM CLOSE (Not Satisfied) |

| Run Feedback | RUN_FB signal received |

🟢 = Run Feedback OK 🔴 = Run Feedback Missing |

| Trip_FB | Trip signal status | = TRIP OK = TRIP |

| TSO (Torque Open) | Torque open limit status | 🟢 = TSO (Limit OK)🔴 = TSO (Limit Not OK) |

| TSC (Torque Close) | Torque close limit status | 🟢 = TSC (Limit OK)🔴 = TSC (Limit Not OK) |

| ZSC (Valve Closed) | Closed feedback status | =ZSC (Feedback Received)= ZSC(Feedback NOT Received) |

| ZSO (Valve Opened) | Open feedback status | =ZSO (Feedback Received)= ZSO(Feedback NOT Received) |

This MOV(Open/Close) faceplate structure ensures full control and monitoring at both operator and supervisor levels.

Best Practices

- Always ensure PERM_OPEN, PERM_CLOSE, and INTERLOCK_OK signals are valid before initiating commands.

- Use the Diagnostic tab for troubleshooting feedback, torque, and trip signals.

- Configure RUN_FB and ZS feedback timeout values appropriately to prevent false fault detection.