Visualization Documentation – MOTOR-REV Block

Usage of MOTOR-REV Block through SCADA Template

The MOTOR-REV block provides control and monitoring of bi-directional motors such as hoists, positioning systems, conveyors, and valves.

In the SCADA Template system, it functions as a reusable visualization component, offering runtime operation, dual-direction control, diagnostics, and feedback.

This block is embedded via a template visualization structure using a pre-configured icon from the Scada_test Visu Page.

- Place the MOTOR-REV block icon into any visualization page and link it with the relevant logic instance.

Integrating the MOTOR-REV Block into Visualization

1. Open the Visualization Page

- Open your CODESYS project.

- Go to the visualization screen where you want the block (e.g.,

Main_HMI,Motor_Control, etc.).

2. Insert the MOTOR-REV Icon from Scada_test Visu Page

- Open the Visualization Toolbox Go to Current Project.

- Drag or drop the MOTOR-REV block icon to your Visualization page.

- Or Just Copy the MOTOR-REV Block Icon from the

Scada_testvisu page and Paste into your Visualization page.

✅ Promotes block reuse and consistency across projects.

3. Link the Icon to Its Logic Block

- Select the inserted MOTOR_Rev block icon.

- click on the block icon Properties tab open automatically → Properties.

- Go to the References and Expand the references.

- you will see bl_motor_L_2d or bl_motor_R_2d or bl_motor_T_2d or bl_motor_T_2d_R Expand that also.

- set the path in front of the tagMotor_rev_fp by Double clicking on empty space and select the required tag.

- Build and run the project.

- During runtime, confirm the motor responds and displays correct feedback.

MOTOR-REV Icon – Status Indicators

Status is visually represented with color-coded indicators

- Clicking the Block Icon opens the motor faceplate.

Faceplate – Overview

The MOTOR-REV faceplate has four operational tabs:

- Operator Tab – Manual control and feedback

- Basic Tab – Summary of run state and conditions

- Advance Tab – Configuration and counters

- Diagnostics Tab – Fault, interlock, and bypass settings

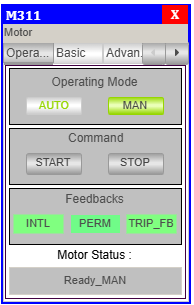

Faceplate - Operator Tab

Operating Mode

- AUTO – Controlled by PLC logic.

- MAN – Manual control via HMI.

The active mode is highlighted in green.

Control Buttons

- START FWD – Start motor in clockwise direction (manual only)

- START REV – Start motor in counter-clockwise direction

- STOP – Stop the motor

Feedback Indicators

| Signal | Meaning |

|---|---|

| INTL | Interlock (🟢 OK / 🟡 Active) |

| PERM FWD | Forward permission (🟢 OK / 🟡 Not met) |

| PERM REV | Reverse permission (🟢 OK / 🟡 Not met) |

| Trip Feedback | Indicates motor fault or trip condition. |

Motor Status

- Current state of the motor is displayed, e.g.,

Running_MAN_FWD,Trip.

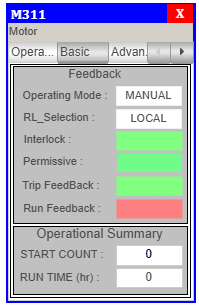

Faceplate - Basic Tab

Basic Parameters

| Parameter | Description |

|---|---|

| Operating Mode | AUTO / MANUAL |

| RL_Selection | LOCAL / REMOTE |

| Interlock | 🟢 OK / 🟡 Interlock Active |

| Perm FWD | 🟢 OK / 🟡 Not Met |

| Perm REV | 🟢 OK / 🟡 Not Met |

| Trip Feedback | 🟢 OK / 🌸 Tripped |

| Run FB FWD | 🟢 Running / 🔴 Not Running |

| Run FB REV | 🟢 Running / 🔴 Not Running |

Operational Summary

- RUN TIME – Total run time of the motor

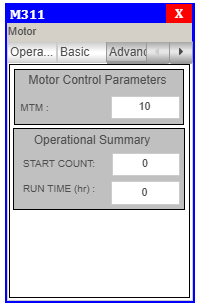

Faceplate - Advance Tab

Configuration and Counters

- RUN TIME – Total time in operation

- Additional engineering parameters can be added as needed.

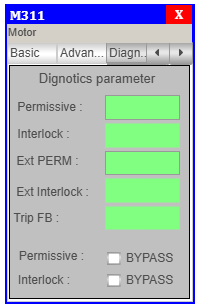

Faceplate - Diagnostics Tab

Diagnostics & Bypass Options

| Item | Color Code | Bypass Available |

|---|---|---|

| Perm FWD | Green = OK, Yellow = Not Met | ✅ Checkbox |

| Perm REV | Green = OK, Yellow = Not Met | ✅ Checkbox |

| Interlock | Green = OK, Yellow = Active | ✅ Checkbox |

| Trip | Green = OK, Magenta = Tripped | ❌ (Read-only) |

Engineer-level users can toggle bypass checkboxes for testing and commissioning.

Integration Notes

- Assign the correct logic variable to

Element Variable. - Test both forward and reverse operations in manual mode before enabling automatic logic.

- Use interlock and permissive feedbacks for fail-safe operation.

- Display trip conditions using SCADA alarm banners.

Summary

The MOTOR-REV block enables complete control and monitoring of bidirectional motors through the SCADA Template system.

✅ Forward and Reverse control

✅ Real-time status with icon colors

✅ Operator, Basic, Advance & Diagnostic tabs

✅ Bypass settings for engineering users

✅ Easy integration using pre-configured templates

Ensures flexible, safe, and standardized control for bidirectional motor operations in your automation projects.