MOV (Open/Close) Logic Block Documentation

Overview

The Motorized Operating Valve (MOV) is a vital component in industrial automation and fluid control systems. Designed for ON/OFF control, it facilitates automated flow regulation through electrically driven actuators, governed primarily by a Programmable Logic Controller (PLC).

-

MOVs are extensively used in process industries—such as oil and gas, water treatment, chemical manufacturing, and power generation—where reliable and responsive flow control is essential.

-

It supports both automatic and manual control modes, permission checks, interlock validation, command execution, and signal-based fault detection. The block outputs critical feedbacks to the HMI faceplates for operator, basic, advanced, and diagnostic views.

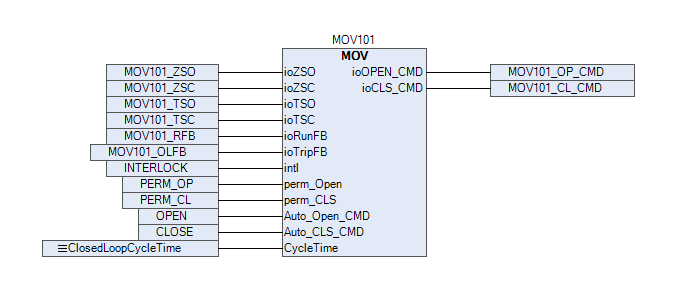

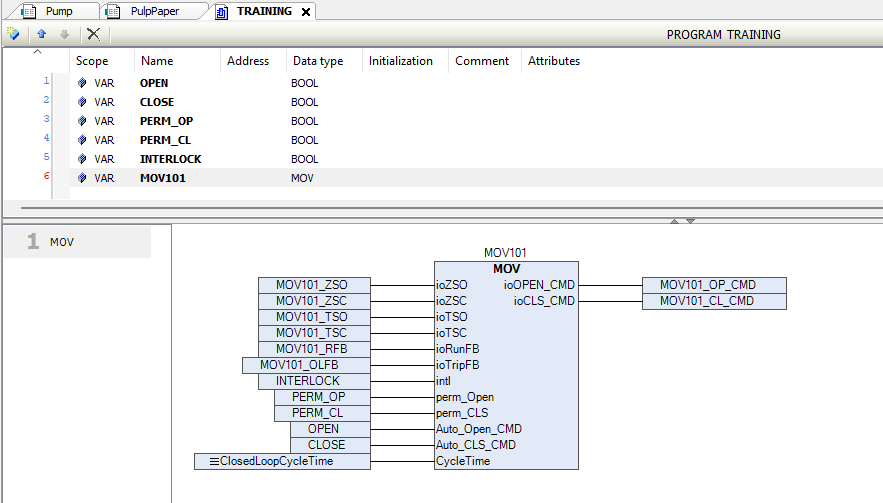

Logic Block Illustration

The MOV logic block provides a structured interface for automating and monitoring a motor-operated valve within a PLC-based control system. This block handles the execution of control commands, feedback processing, alarm generation, and interlock checks.

A visual representation of the MOV block showing its place in the logic and I/O system.

In the above picture, we are showing that how to use the MOV_Inching block.

Pins Information

| Signal | Type | Description |

|---|---|---|

ioZSO |

BIT | Valve Open Feedback – Indicates valve is fully open. |

ioZSC |

BIT | Valve Close Feedback – Indicates valve is fully closed. |

ioTSO |

BIT | Torque Open Feedback – Torque switch signal when valve opens. |

ioTSC |

BIT | Torque Close Feedback – Torque switch signal when valve closes. |

ioRunFB |

BIT | Feedback indicating the motor is running. |

ioTripFB |

BIT | Indicates motor tripped (protection relay). |

HMI_Open_CMD |

BIT | Valve Open command from HMI. |

HMI_CLS_CMD |

BIT | Valve Close command from HMI. |

Auto_Open_CMD |

BIT | Valve Open command from other logic blocks (Auto mode). |

Auto_CLS_CMD |

BIT | Valve Close command from other logic blocks (Auto mode). |

Mode |

BIT | Manual = 0, Auto = 1. |

ioOPEN_CMD |

BIT | Output signal to open the valve. |

ioCLS_CMD |

BIT | Output signal to close the valve. |

perm_Open |

BIT | External permissive for Open command. Must be TRUE to allow motion. |

perm_CLS |

REAL | External permissive for Close command. |

intl |

BIT | External interlock. TRUE means interlock is active and motion is blocked. |

FB_Fault |

BIT | ZSO/ZSC not received within configured time. |

CMD_Fault |

BIT | Run feedback not received after command OR feedback received without command. |

unrecog_operation |

BIT | Valve is running without valid open/close feedback, e.g., inconsistent state. |

Run_FB_Timer |

REAL | Configured time to wait for motor run feedback after issuing command. |

Run_FB_Counter |

REAL | Runtime counter while waiting for motor run feedback. |

ZS_Timer |

BIT | Activates during valve travel from ZSO → ZSC or ZSC → ZSO. |

ZS_Counter |

REAL | Runtime duration of valve movement. |

opened_time |

REAL | Time duration the valve has been open. |

closed_time |

REAL | Time duration the valve has been closed. |

open_count |

DINT | Number of valve open operations (count). |

close_count |

DINT | Number of valve close operations (count). |

R_Trig_ZSO |

R_TRIG | Rising edge trigger for Open feedback. |

R_Trig_ZSC |

R_TRIG | Rising edge trigger for Close feedback. |

valve_running |

BIT | Internal signal indicating valve is in motion. |

HMI_Interface_hardware |

WORD | Hardware interface data exchanged with HMI. |

CycleTime |

REAL | Main program cycle time of logic block. |

Desc |

STRING(10) | Tag name of the MOV block (max. 10 chars). |

TagName |

STRING(12) | Description of the MOV block (max. 12 chars). |

Operational Summary

- The logic block operates in Manual (HMI control) or Auto (external logic) mode.

- Only one command is executed at a time (either open or close).

- Safety interlocks and permissives are evaluated before any valve motion.

- If feedback is missing or inconsistent, fault flags are raised.

- Motion duration and state transitions are monitored using ZS_Timers and Run Feedback Timers.

- Usage analytics (open/close count and duration) are tracked for diagnostics and maintenance.

Training Demo Video

Demonstration video is available , How to use the Daca Logic Block through Library:

MOV-ON/OFF Block Demo - TPW Logic Setup

Best Practices

- Always validate PERM_OPEN, PERM_CLOSE, and INTERLOCK before allowing valve movement.

- For safety, faulted valves (TRIP state) must be reset manually using the faceplate Reset button or

RESETpin. - Keep

RUN_FB_TIMEOUTandZS_FB_TIMEOUTparameters conservative to avoid false positives in slow-acting valves.

Tip:

This logic ensures synchronized operation between field signals and faceplate visualizations, enabling safe and operator-friendly MOV control.