SOV_SA (Single Acting Solenoid Valve) Logic Block Documentation

Overview

The SOV_SA logic block is used to control single-acting solenoid valves with spring return mechanisms, typically for fail-safe operations. It supports both automatic and manual control, checks for permissions and interlocks, monitors feedback status, and detects faults such as feedback timeouts. The block interfaces directly with HMI faceplates across Operator, Basic, Advanced, and Diagnostic levels.

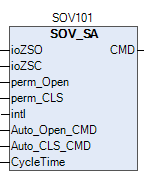

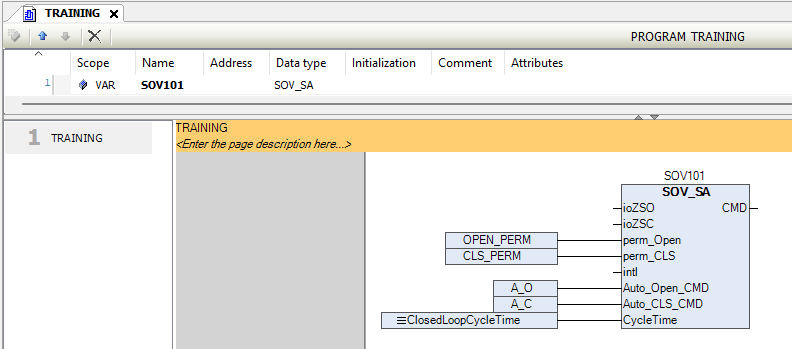

Logic Block Illustration

In above picture, we are showing inputs and output of SOV-DA block.

- A visual representation showing how the SOV-SA block connects with inputs, outputs, and HMI indicators.

In the above picture, we are showing that how to use the SOV-DA block

Pins Information

| Signal Name | Type | Description |

|---|---|---|

| CMD_OPEN | BOOL | Manual open command from faceplate |

| CMD_CLOSE | BOOL | Manual close command from faceplate |

| MODE | BOOL | 0 = Auto mode, 1 = Manual mode |

| AUTO_CMD | BOOL | Auto mode command input (TRUE = Open) |

| PERM_OPEN | BOOL | Permission to open valve |

| PERM_CLOSE | BOOL | Permission to close valve |

| INTERLOCK_OK | BOOL | TRUE = Interlock condition satisfied |

| ZSO_FB | BOOL | Valve fully open feedback |

| ZSC_FB | BOOL | Valve fully closed feedback |

| ZS_TIMEOUT_SEC | TIME | Timeout to wait for feedback after command |

| RESET | BOOL | Clears faults when TRUE |

| TAG_NAME | STRING | Unique name for this valve block |

| DESC | STRING | Block description shown on faceplate |

| CMD_OUT | BOOL | Output to solenoid coil |

| VALVE_OPEN | BOOL | Valve is confirmed open |

| VALVE_CLOSE | BOOL | Valve is confirmed closed |

| CMD_FAULT | BOOL | Feedback fault detected (timeout or mismatch) |

| STATUS | BYTE | 0 = Closed, 1 = Open, 2 = Fault, 3 = Running |

| OPEN_COUNT | UDINT | Total number of successful valve openings |

| CLOSE_COUNT | UDINT | Total number of successful valve closings |

| OPENED_TIME | TIME | Cumulative time valve has remained open (Hrs) |

Operational Behavior

Mode Selection

- Auto Mode (

MODE = 0): - Valve is driven using the

AUTO_CMDinput. -

Only executed if

PERM_OPEN,PERM_CLOSE, andINTERLOCK_OKare TRUE. -

Manual Mode (

MODE = 1): - HMI buttons (

CMD_OPEN/CMD_CLOSE) are active. - Commands are validated using permissions and interlock

Command Evaluation

- Valve commands are only executed if:

- The corresponding PERM_OPEN or PERM_CLOSE is active.

- The INTERLOCK_OK condition is TRUE.

Output Activation

CMD_OUTis turned ON when the command conditions are met and the valve is expected to change state.

Status Handling

| STATUS Value | Meaning |

|---|---|

0 |

Valve is fully closed |

1 |

Valve is fully open |

2 |

Command fault has occurred |

3 |

Valve is in transition (Running) |

VALVE_OPENandVALVE_CLOSEindicate real-time valve position.CMD_FAULTflags incorrect or delayed feedback signals.

Fault Detection

| Fault Condition | Signal Affected |

|---|---|

No open feedback (ZSO_FB) after open cmd |

CMD_FAULT = TRUE |

No close feedback (ZSC_FB) after close cmd |

CMD_FAULT = TRUE |

| Missing permission or interlock | Command is blocked |

- Timeout for feedback is governed by

ZS_TIMEOUT_SEC. - Faults are latched until the user resets using the

RESETpin or faceplate button.

Output Summary

- CMD_OUT: Direct control output to energize the solenoid.

- VALVE_OPEN / VALVE_CLOSE: Used for HMI indicators.

- CMD_FAULT: Signals that expected feedback was not received.

- STATUS: Encoded status for faceplate state visualization.

- OPENED_TIME_SEC: Tracks duration when valve is open.

- OPEN_COUNT / CLOSE_COUNT: Track operation cycles.

Notes for Integration

- Always link

CMD_OUTto the coil actuator output in hardware. - Use

ZSO_FBandZSC_FBfrom physical limit switches or position sensors. - HMI faceplate should reflect the following:

- Mode selector (Auto/Manual)

- Command buttons (OPEN/CLOSE)

- Fault reset button

- Feedback indicators (Open/Closed)

- Alarm banner if

CMD_FAULTis active - Use

TAG_NAMEandDESCfor diagnostics and navigation in SCADA.

Best Practices

- Ensure all control signals (permissions and interlocks) are validated before actuation.

- Configure

ZS_TIMEOUT_SECconservatively based on valve response speed. - Maintain consistent naming using

TAG_NAMEfor SCADA traceability. - Use runtime counters and fault detection for predictive maintenance dashboards.

The SOV-SA block ensures safe, responsive control of spring-return solenoid valves, with built-in feedback validation and HMI integration for intuitive operator control and diagnostics.