MOV_INCH – Logic Block Documentation

Overview

The MOV_INCH block is designed to control Motor Operated Valves (MOVs) with inching functionality. It is widely used in industrial automation to allow precise, step-wise operation of valves, providing both automatic and manual (HMI-based) control. This document details the logic behavior, input/output signals, and operational parameters of the MOV_INCH logic block.

- The block ensures that all operational constraints such as interlocks, permissions, feedback, and timeouts are satisfied before commanding valve operations.

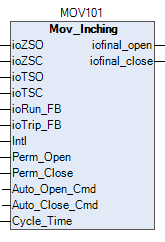

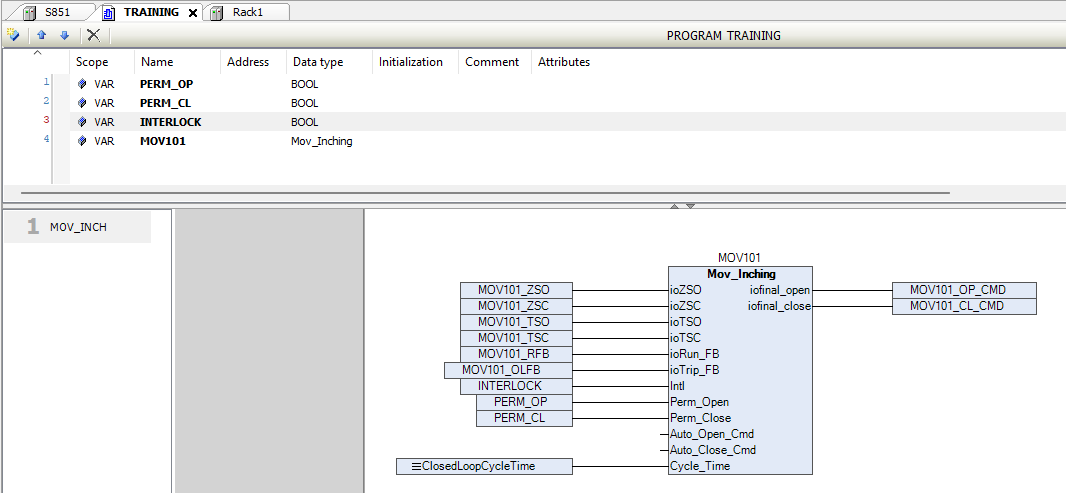

Logic Block Illustration

- A visual representation of the MOV_INCH block showing its place in the logic and I/O system.

- Example diagrams include input/output wiring and HMI control integration.

In above picture, we are showing inputs and output of MOV_Inching block.

In the above picture, we are showing that how to use the MOV_Inching block.

Pins Information

| Signal | Type | Description |

|---|---|---|

ioZSO |

BIT |

Valve Open Feedback – Indicates valve is fully open. |

ioTSO |

BIT |

Torque Open Feedback – Torque switch signal when valve opens. |

ioTSC |

BIT |

Torque Close Feedback – Torque switch signal when valve closes. |

ioZSC |

BIT |

Valve Close Feedback – Indicates valve is fully closed. |

ioRunFB |

BIT |

Feedback indicating the motor is running. |

ioTripFB |

BIT |

Indicates motor tripped (e.g., via protection relay). |

HMI_OPEN_INCH |

BIT |

Momentary command from HMI to inch the valve open. |

HMI_CLOSE_INCH |

BIT |

Momentary command from HMI to inch the valve close. |

AUTO_OPEN_INCH |

BIT |

Momentary open inch command from other logic (Auto mode). |

AUTO_CLOSE_INCH |

BIT |

Momentary close inch command from other logic (Auto mode). |

Mode |

BIT |

Manual = 0, Auto = 1. |

ioOPEN_CMD |

BIT |

Output signal to open the valve (momentary pulse). |

ioCLS_CMD |

BIT |

Output signal to close the valve (momentary pulse). |

perm_Open |

BIT |

External permissive for open command. Must be TRUE to allow operation. |

perm_CLS |

BIT |

External permissive for close command. |

intl |

BIT |

Interlock. TRUE means interlock is active and motion is blocked. |

FB_Fault |

BIT |

ZSO/ZSC not received within the configured window. |

CMD_Fault |

BIT |

Run feedback not received after command or received unexpectedly. |

unrecog_operation |

BIT |

Valve is running but feedback is missing or inconsistent. |

Run_FB_Timer |

REAL |

Time allowed for RunFB to respond after command is issued. |

Run_FB_Counter |

REAL |

Runtime counter while waiting for motor run feedback. |

ZS_Timer |

BIT |

Active while valve is moving (ZSO → ZSC or vice versa). |

ZS_Counter |

REAL |

Time duration of current valve movement. |

opened_time |

REAL |

Total accumulated open time. |

closed_time |

REAL |

Total accumulated close time. |

open_count |

DINT |

Number of open inching operations. |

close_count |

DINT |

Number of close inching operations. |

R_Trig_ZSO |

R_TRIG |

Rising edge trigger for Open feedback signal. |

R_Trig_ZSC |

R_TRIG |

Rising edge trigger for Close feedback signal. |

valve_running |

BIT |

TRUE when the valve is in motion. |

HMI_Interface_hardware |

WORD |

Interface data exchanged with HMI. |

CycleTime |

REAL |

Execution cycle time of the logic block. |

Desc |

STRING(10) |

Short description or tag (max. 10 characters). |

TagName |

STRING(12) |

Valve identifier (max. 12 characters). |

Operational Summary

- The MOV_INCH block allows inching (momentary jog) control in Manual (HMI) or Auto (logic) mode.

- Inching commands must be momentary pulses; each pulse causes a small valve movement.

- Only one command (open or close) is active at any time.

- Before executing commands, permissives and interlocks are validated.

- Feedback signals (

ioZSO,ioZSC,ioRunFB) confirm valve position and motion. - Fault detection logic ensures command execution is verified by feedback within time limits.

- Timers and counters track runtime, usage analytics, and valve behavior.

- Intended for valves requiring precise, short-step motion with high control granularity.

Training Demo Video

Demonstration video is available , How to use the MOV_INCHING Logic Block through Library:

MOV-INCH Block Demo - TPW Logic Setup

Best Practices

- Always validate

PERM_OPEN,PERM_CLOSE, andINTERLOCKbefore motion. - Use rising edge detection (

ZSO_TRIG,ZSC_TRIG) to count operations accurately. - Set inching command pulse duration and timeout (

INCH_TIMEOUT) based on actuator specs. - Use conservative values for feedback timeouts to prevent false positives.

- Manually reset faults and trips after resolving physical or electrical issues.

End of MOV_INCH Logic Block Documentation