MV_SPLIT (Split Range Controller) Logic Block Documentation

Overview

The MV_SPLIT block is an essential control module in process automation systems designed to implement split-range control. It allows a single manipulated variable (MV)—typically from a PID or control logic—to be distributed across two separate actuators (e.g., control valves or dampers) based on predefined ranges.

This logic is commonly used in: - Temperature control (heating/cooling valves) - Flow control (dual parallel valves) - Pressure control systems

By managing how each actuator responds to different ranges of the MV, the block ensures: - Smooth transitions - Optimized actuator usage - Improved loop stability

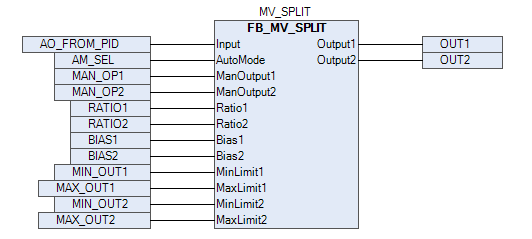

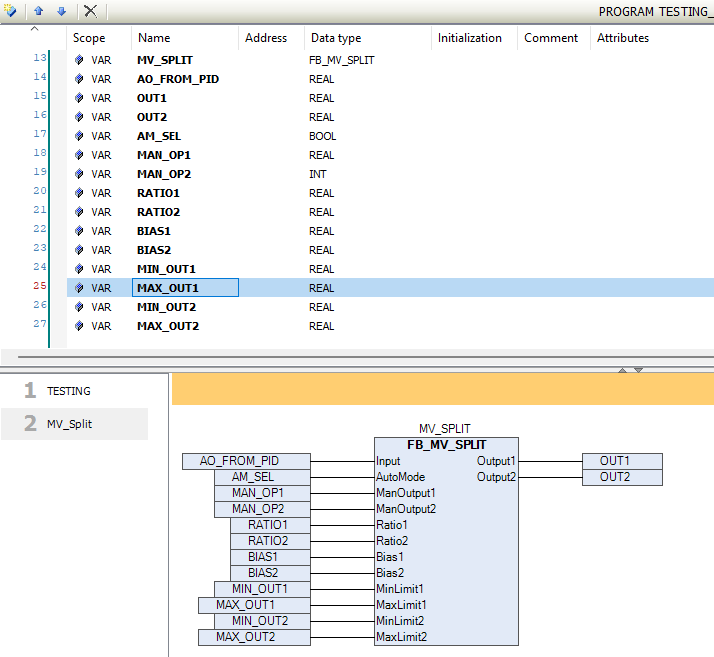

Logic Block Illustration

The MV_SPLIT logic block is used to control and monitor a split-range control valve, typically used in analog control loops. It divides the input signal to operate two actuators or two ranges of a single actuator, allowing fine-grained control over a wider operational range.

A visual representation of the MV_SPLIT block, showing its function in distributing a single control signal into two separate actuator signals, depending on the configured range.

The above pictures show how the inputs and outputs are connected in the MV_SPLIT block.

This illustration shows the correct signal mapping and usage of the MV_SPLIT block within a process automation program, including control signal ranges and output behavior for dual-valve control.

Functional Description

- In Auto Mode, the block uses the

InputMV signal and calculates the outputs based on: - Defined limits (

MinLimit1,MaxLimit1, etc.) -

Ratios and biases (

Ratio1,Bias1, etc.) -

In Manual Mode, users can directly set outputs using:

ManOutput1andManOutput2

This allows for both automated split control and manual override during commissioning or testing.

Input and Output Parameters

| Signal | Type | Description |

|---|---|---|

Input |

REAL |

Main manipulated variable (MV) typically from PID |

AutoMode |

BOOL |

Mode selection: TRUE = Auto, FALSE = Manual |

ManOutput1 |

REAL |

Manual override value for Output1 |

ManOutput2 |

REAL |

Manual override value for Output2 |

Ratio1 |

REAL |

Scaling ratio for Output1 |

Ratio2 |

REAL |

Scaling ratio for Output2 |

Bias1 |

REAL |

Bias (offset) for Output1 |

Bias2 |

REAL |

Bias (offset) for Output2 |

MinLimit1 |

REAL |

Minimum clamp for Output1 |

MaxLimit1 |

REAL |

Maximum clamp for Output1 |

MinLimit2 |

REAL |

Minimum clamp for Output2 |

MaxLimit2 |

REAL |

Maximum clamp for Output2 |

Output1 |

REAL |

Final calculated Output1 value |

Output2 |

REAL |

Final calculated Output2 value |

Operational Logic

🔄 Auto Mode (AutoMode = TRUE)

- Output values are automatically calculated based on the live

Input, adjusted byRatioandBias, and bounded within definedMinandMaxlimits.

🔧 Manual Mode (AutoMode = FALSE)

- Allows the operator to directly assign values to

ManOutput1andManOutput2. - Useful in the following cases:

- 🔧 Plant commissioning and tuning

- 🚨 Manual override during fault or abnormal conditions

- 🔄 Temporary bypass of automation logic

- Outputs are still clamped between the configured limits to ensure safety and consistency.

Training Demo Video

Demonstration video is available , How to use the MOV_INCHING Logic Block through Library:

MV-Split Block Demo - TPW Logic Setup

Use Case Scenario

💡 Example 1: Valve Split Control

- Valve 1: operates from 0%–50% MV

- Valve 2: operates from 50%–100% MV

```text

Ratio1 = 1.0, Bias1 = 0, MinLimit1 = 0, MaxLimit1 = 50

Ratio2 = 1.0, Bias2 = -50, MinLimit2 = 0, MaxLimit2 = 50